-

-

1. Client needs

Client identifies the need of a new sealing product for a specific bottle, flask or valve.

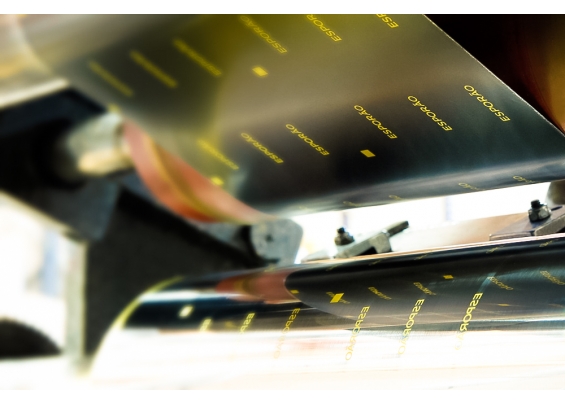

Client defines type of printing and / or stamping to be incorporated in the product according to the intended design; -

2. Identification, analisis and development

It is required to the Client all the information needed for the product analisis, for example, drawings and or sample of bottles, flasks or valves.

It is checked the feasibility of the product;

It is determined dimensional characteristics adapted to the packing base material, and incorporation of the artwork in the product;

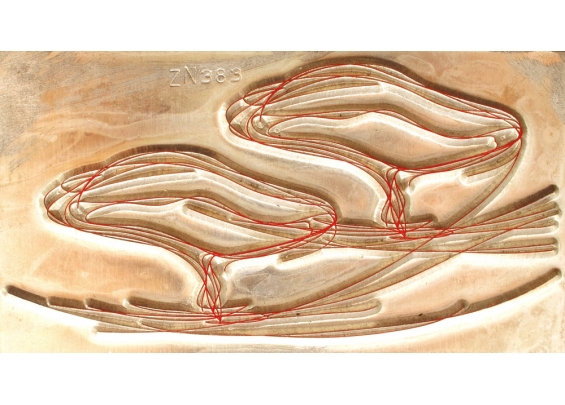

It is allocated necessary tools, new or existing, for implementing the product; -

3. Elaboration of the proposal for approval

Elaboration of the proposal with the conditions of product supply;

Conditions of product supply covers aspects such as deadlines, quantities, budgets, indispensable tools to run, etc ...

This proposal is accompanied by a drawing for approval performed by Cápsulas do Norte design team; -

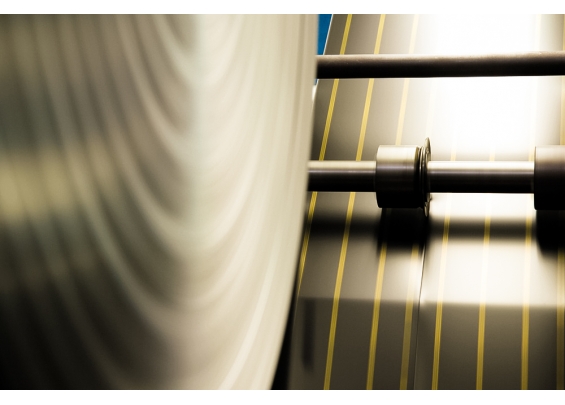

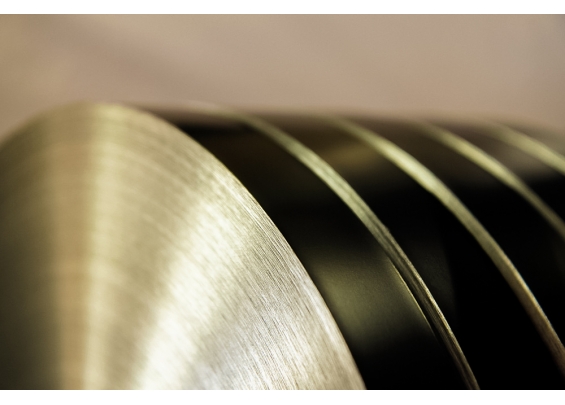

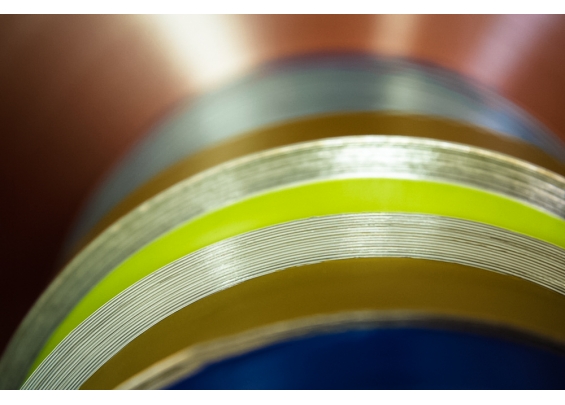

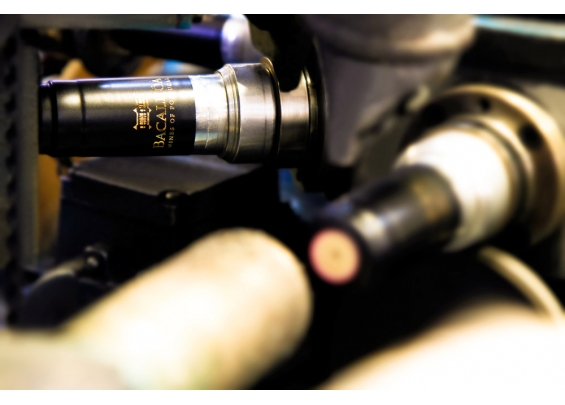

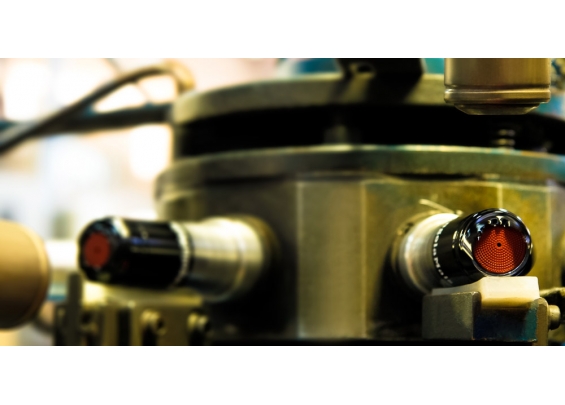

4. Production

The approval of the proposal gives way to the order of the product which then goes into the production planning;

It is gathered all the information needed to run the product, raw material, tools, etc.

After production, the product is subjected to a final inspection in order to verify its conformity with the specifications approved. The finished product is stored in boxes properly identified, making reference to aspects such as product batch, date of manufacture, among others, in order to make it possible to trace the product; -

5. Delivery and post-sales support

Finalized orders are routed to the finished product warehouse;

The delivery follows in accordance with what has been previously defined with the Client.